Our EPC Expertise

Range of Activities

- Designing and Manufacturing of Water Tube Boilers ranging from 20 TPH to 200 TPH, Pressure ranging 32-125kg/cm2

- EPC Co-generation for Sugar Plants and Captive Power Plants for Process Industries on Turnkey Basis

- Incineration Boilers for Zero Liquid Discharge (ZLD)

- Waste to Energy Project on EPC Basis

- Boiler Automation – DCS/PLC systems

- Electrical Power Distribution System & Export of Power

- Boiler Upgradation: Revamping & Refurbishing, Enhancing Capacity and Efficiency of Existing Boilers

- Civil Foundations, Plant Buildings and RCC Chimney

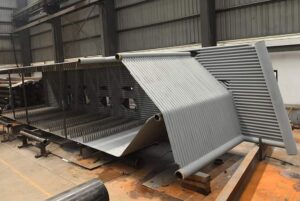

- Supply and Erection & Commissioning of Pressure Parts: Water Wall Panels, Economizer, Super Heater Coils, Evaporator, Bank Tubes, HP Heater, Headers and all IBR Piping

- Supply and Upgradation of Instrumentation and Control Equipment's

EPC Power Generation Plant with Civil work

- Turbine and Its Auxiliaries (DEC/BP)

- Power Distribution system (HT/LT) for Cogen and Process Plant

- Complete External Piping, Pipe Rack and Its Supports

- Plant Automation With DCS /PLC Scada

- TG shed and Control Room

- EOT Crane for Power House

- Plant Water System (Pretreatment/DM-RO plant)

- Compressor and Instrument Piping and Cabling

- Air Conditioning and Ventilation for TG hall

- Cooling Tower (Air Cooled/Water Cooled), Its Pumps and Piping

- Fuel Shed

- Power Export Switch yard

- Civil Design, Civil Foundations and Civil Building

- Transportation, Transit Insurance

- Erection and Boiler Erection, Commissioning

- Complete Plant Lighting

- First Fill Lubricants, Commissioning Spares

One Stop Shop Solution for all EPC & Related Requirements

Design

Manufacture

Erect

Commission

Deliver

Boilers / Steam Generators

- Boiler Pressure Parts & Boiler Auxiliaries

- Boiler Supporting Structure, Ducting, Grating, Railing, Canopy Sheet, Casing, Hoppers Etc.

- ESP (3/4/5 Field), CEMS

- External Water Piping

- Boiler Electricals, MCCs and Cabling

- Boiler Instrumentation

- Fuel Handling system and Fuel Feeding System

- Ash handling system

- Boiler Chimney, Aviation Lighting

- IBR Approval and Documentation

Pressure Part Contract Manufacturing

Privilege Biksons Boilers Pvt. Ltd. operates advanced production facilities, strictly adhering to ISO 9001 quality standards. The company specializes in manufacturing and supplying pressure vessels, including steam boilers, drums, accumulators, decelerator tanks, storage tanks, and steam piping. Additionally, they produce non-pressure components like chimneys, tankages, and structural elements based on clients' manufacturing drawings. Beyond manufacturing, they offer engineering services for converting process drawings into detailed production drawings.